Export materials and products

Export materials and products

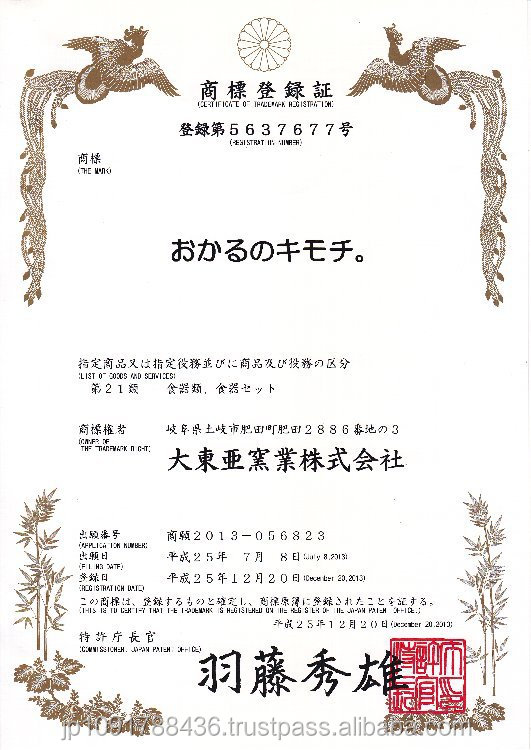

The ceramics are produced in Toki, Gifu Prefecture, which is well known as the origin of Mino Ware and is Japan’s largest pottery production region. Okaru-no-Kimochi

Lightweight reinforced porcelain. It is robust and easy to clean. Very light. There is a variety of product ranges.

Easy to use and Reliable cooking pottery with multiple functions made in Japan

== New light reinforced ceramics==

The ceramics which are kind to all people concerned with a meal

Actual features of our domestic plant

1.Providing products with stability, relief and safety

2.Cost reduction by shorter lead time

3.Prompt feedback for the quality improvement

4.Offering abundant variety of products in shape, material and decoration

Features

1 .The ceramics are strong and light, that are hard to break

Light=be easy to break, Strong=heavy

The ceramics overturn above the concept.

2 .The ceramics are hard to get dirty, and easy to clean

Because we use the glaze that are finer than general glaze.

3. Temperature of the ceramics are hard to change (It is hard to be cool down)

It is superior to conventional products in terms of moisture retention.

The temperature of ceramics oneself are hard to change,

ceramics are hard to be warm even if we serve warm foods.

Manufacturing Process

1.Kneading soil

Knead soil that is combined natural materials, it could make homogeneous dough by using the machine.

2.Molding

Mold products form. By using all automatic molding machine, it supports various mass production systems.

3.Unglazed pottery

After products were dried well, they are burned by all automatic kilns of 900 degrees and give them strength.

4.Muffle painting

By using silicon pad, they are printed a pattern directly.

5.Glazing

Glazing is work to coat the surface of products, this process is the most important in expressing beauty of products.

6.Firing pottery

Finally, firing products by kilns of 1230 degrees.

7.Inspection

Inspection fired the products, and process bottom of every ceramics.

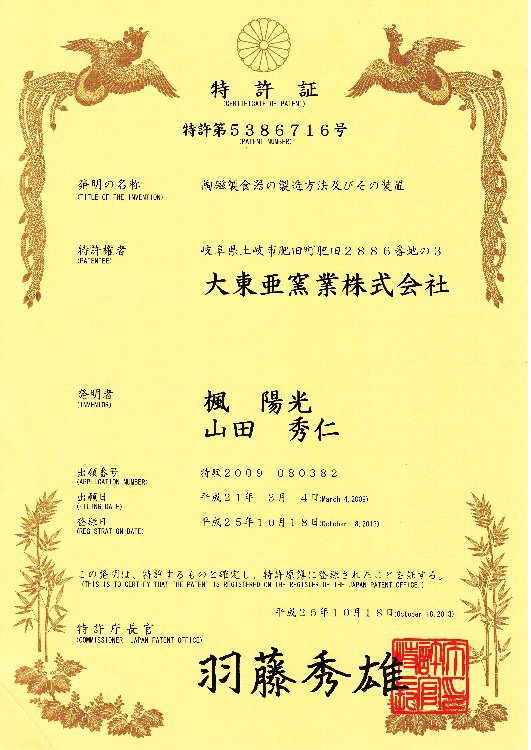

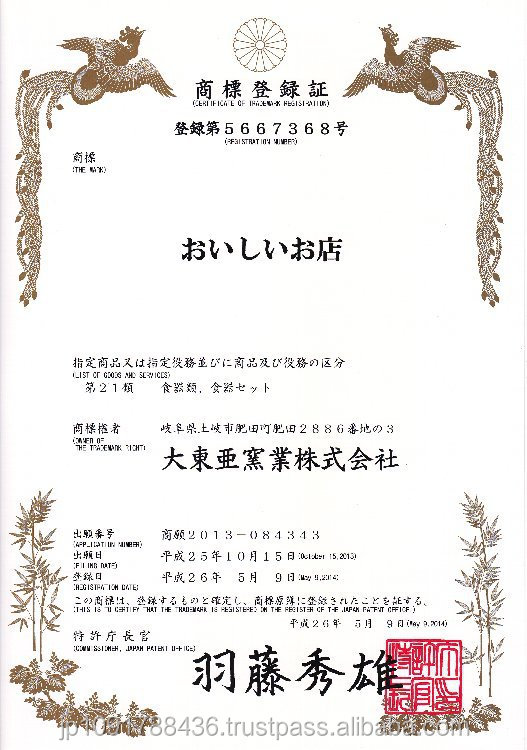

Diploma

We are a member of Showa Concrete Industry Group.